The Mosfets have been selected and precision matched, each individual modules has

the closest match out of hundreds of Mosfets!!

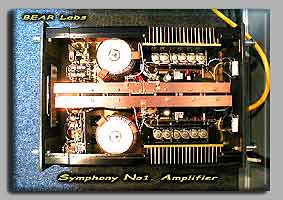

Inside the Symphony No.1 Amplifier

Inside the Symphony No.1 Amplifier

Here's a picture of the Mosfet modules before

they are fastened to the heatsinks.

The Mosfets have been selected and precision

matched, each individual modules has

the closest match out of hundreds of Mosfets!!

Now you see the module before the Main Amp

PCB is attached and wired in. You can

see the 10ga. wire that is soldered to the

Mosfets. This sends the rail voltage in and

takes the signal back out, with ample current

capacity to spare. I do not use push on

type plugs or connectors anywhere in this

amplifier - all connections use high quality

silver bearing solder - this assures solid,

low resistance connection, and the longest

operational life without breakdown.

.jpg)

Also, note the high quality hardware that

is employed. It is all 100% Stainless Steel

machine screws and nuts. In this image the

standoffs are plated brass. There is nothing

to rust. Note how the Mosfet's module is

fastened to the heatsink! Multiple precision,

CNC machined holes are made in the heatsink,

and in the brackets the holes are tapped.

This provides a very tight fit between the

brackets and the heatsinks to maximize the

efficiency of heat transfer.

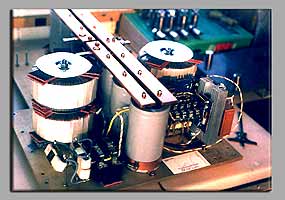

This is the power supply under construction.

This is the power supply under construction.

You can see the heavy 5/16" aluminum alloy

chassis. Mounted on that chassis are the soft

start relays (to cushion the turn on current),

the control circuit for them, as well as the

power resistors that actually do the work

during the soft start. One can't use a regular

switch to control a power supply of this

size - regular switches would "die young" handling

this load. So, I use relays that have multiple

high-current contacts, and then I use them all

in parallel to minimize the contact resistance!

Each of the contacts is 1/4" in diameter -

compare that to the contact size of even

a 20 amp rocker switch!! Down the center are the

filter capacitors. This bank of caps has

a total capacitance of over 500,000 ufd.!! This

is half a FARAD! In order to transfer the

current and keep the voltage drop low the bank

of capacitors is tied together with solid

copper buss bars that are 1" wide and 1/4" thick.

Then behind that are 4 stacked toroidal

power transformers for a total of over 2.5kVA of

available power.

There's more to come... the rest of the story is being prepared...

When it is all done, this is what it looks

like with the top open!!